How 3D Printing Will Transform Business

March 10, 2015

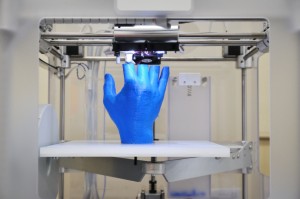

This article explains how 3D printing is already changing business models. 3D printing is an additive manufacturing (AM) process in which parts are grown rather than subtracted, such as with traditional machining. The process is now producing products at the same quality level as traditional machining, but with less capital investment. 3D printing is being used by young entrepreneurs as well as industry giants, producing products as intricate as patient-specific cranial implants and nozzles for aircraft jet turbines. The technology will continue to spark innovation as design engineers can develop value-engineered products according to individual needs and tastes, and quickly produce small runs inexpensively, even from the home or office. This will promote domestic production and re-shoring, as products will be built where they will be sold, and only at the necessary volumes – saving on inventory, shipping, and exchange rates. It will completely change supply-chain economics.

Click here to read the full article in Forbes.