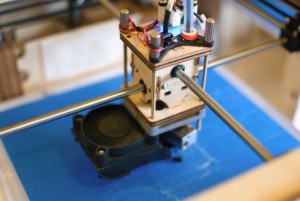

A New Wave for 3D Printed Electronics

February 24, 2015

Recent research by a team made up of professionals from University of Chicago, Argonne National Laboratory, and the Illinois Institute of Technology has demonstrated a way that semiconductors could be soldered together using a new solder material, 3D printed and display the proper electronic performance. The new solder is made up of cadmium, lead, and bismuth and can join semiconductors in liquid or paste format. Traditional semiconductor manufacturing does not use solder, but the new research will help open the possibilities for some working with semiconductors. It won’t likely affect mainstream manufacturing, but will help smaller companies and specific markets with less expensive solutions for printable electronics, including 3D printing, flat panel display manufacturing, solar cells and thermoelectric heat-to-electricity generators.

Click here to read the full article in 3Dprint.com.